"We've been in the business a long time and always interested in trying new, innovative things. 3D printed dentures have proven to be an excellent choice and Materflow a sound partner."

- Kalevi Epäilys, senior dental technician

Palokan Hammas is a well-known dental service provider in the Central Finland area with over 25 years of experience in dental health including their own laboratory and technician service.

Our co-operation with Palokan Hammas extends to manufacturing of dental plates and bridge frames from remanium star CL with SLM metal 3D printing. Over the years the workflow has become simple and straightforward: Palokan Hammas provides us the CAD/CAM models they design for their clients, we print the final products, and ship them back to Palokan Hammas or directly to their client.

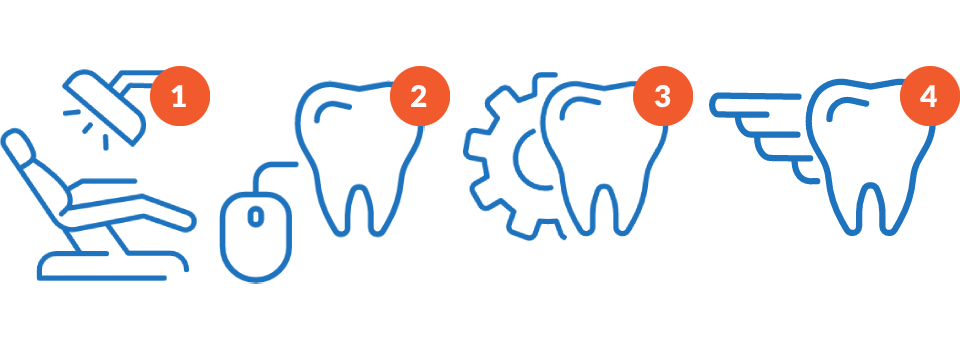

Workflow

1. SCAN – A dentist or dental lab collects patient anatomy digitally or scans a physical model or impression.

2. DESIGN – The dentist or dental lab imports the scan data into CAD software and designs/builds/restores the model.

3. 3D PRINT – The dentist or dental lab sends the CAD/CAM model files to Materflow for manufacturing.

4. SHIP – After manufacturing, post processing, and quality check-up we’ll ship the products to the dentist or lab. The whole process takes usually 3-6 business days.

Patient information and data protection is important to us. We use secure systems and selected staff members to process the information and orders we receive. Our equipment and manufacturing processes comply with the 93/42/EEC Medical Device Directive.